1) High Hardness: Surface hardness of steel grinding ball is to 60-68 HRC and volume hardness of grinding balls is to 60-65 HRC;

2) High Impact Toughness: The impact toughness is higher than 15 J/cm2;

3) Low Broken Rate: The actual broken rate is not higher than 1%;

4) Even Wear-resistance: The wear rate of cast ball is 50-700 g/ton.

1. Feature

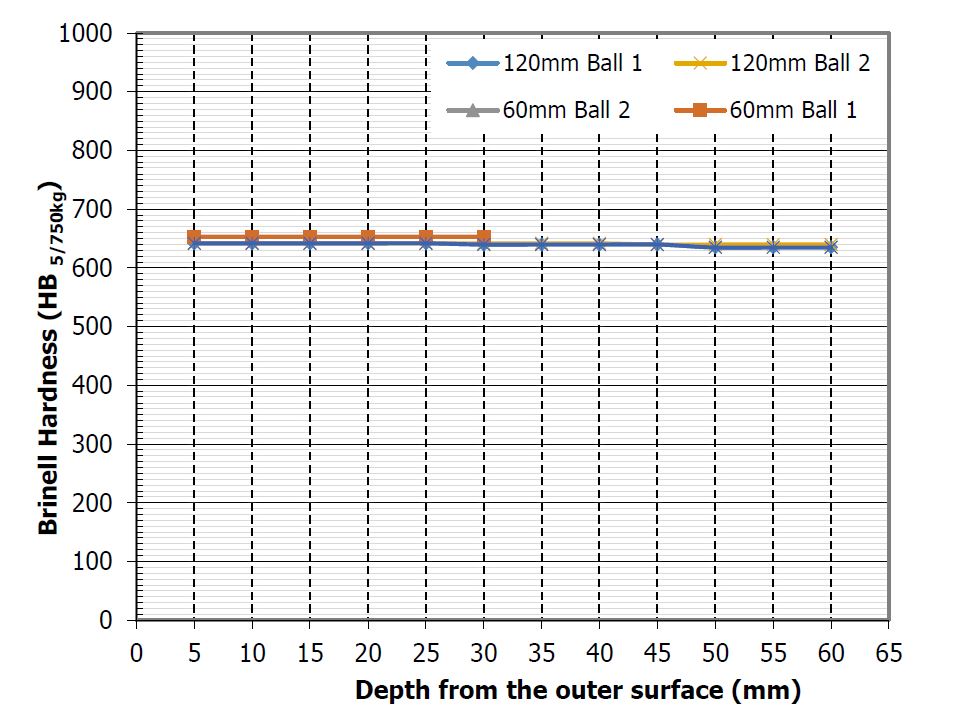

1) As our test report of Mintek, the hardness of the 25mm-100mm Balls is consistent from surface to centre. The hardness of the 110mm-140mm Balls is consistent and decreases slightly from surface to centre. Basically the hardness influences the toughness and the abrasion resistance of the grinding ball. The higher the hardness, the higher the abrasion resistance.

2) All our tested balls passed the drop test without any signs of spalling for 12000 drops.

3) The microstructure consist of martensite near the surface. The microstructure at the centre consist of martensite and retained austenite.

4) Even Wear-resistance: Our grinding media show a better wear resistance than others with 50-700 g/ton.

2. Specification of Grinding Ball

| Diameter | Diameter Tolerance | Average Weight per Ball | Average Numbers per Ton | |

| mm | Inch | mm | g | pcs |

| 20mm | 0.75'' | +2 / -1 | 32 | 31250 |

| 25mm | 1'' | 64 | 15625 | |

| 30mm | 1.25'' | 111 | 9090 | |

| 40mm | 1.5'' | 263 | 3802 | |

| 50mm | 2'' | 513 | 1949 | |

| 60mm | 2.5'' | +3 / -2 | 888 | 1126 |

| 70mm | 2.75'' | 1410 | 709 | |

| 75mm | 3'' | 1729 | 578 | |

| 80mm | 3.25'' | 2104 | 475 | |

| 90mm | 3.5'' | 2996 | 333 | |

| 100mm | 4'' | 4110 | 243 | |

| 110mm | 4.5'' | +4 / -2 | 5457 | 182 |

| 120mm | 4.75'' | 7102 | 140 | |

| 125mm | 5'' | 8008 | 125 | |

| 130mm | 5.25'' | +4 / -3 | 9029 | 110 |

| 140mm | 5.5'' | 11278 | 88 | |

| 150mm | 6'' | 13871 | 72 |

3. Hardness from Surface to Centre of Grinding Balls

Grinding balls show through hardness from surface to centre with 60HRC. 120mm ball hardness is consistent and decreases slightly from surface to centre.

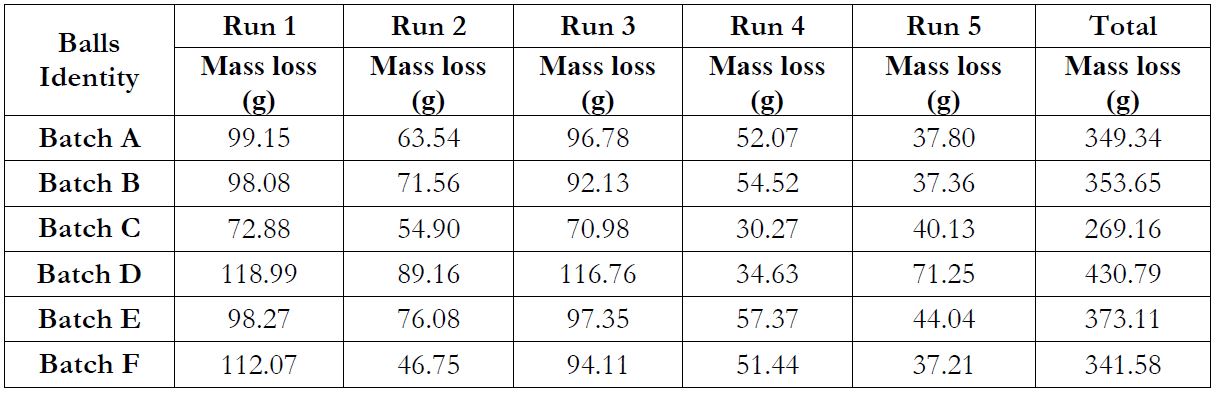

4. Wear Resistance

Our grinding balls show a better wear resistance than others.

Tested balls from each batch of the supplied grinding balls was tested in an experimental ball mill. The grinding balls were individually weighed in preparation for testing in an experimental ball mill of dimensions 600mm diameter x 600mm length. The material charged in the mill consisted of copper-nickel ore (<40mm) supplied by the client. Below is photograph and test result.